UNIVERSAL STAKE FOR SCREW-DOWN CASE-BACKS

Closing and opening

THANKS to its adhesion, this stake is suitable for all types of case-back. So it will replace all dedicated stake panels

This stake's 2 main assets are the excellent adhesion of the sphere, as well as the adjustable stop used to optimise the contact surface on the case-backs.

This adhesion, associated with a maximum contact surface, makes it possible to screw the case-backs to the final tightening torque. To do so, it is preferable to mount the stake on a press combining vertical movement (ideally a rack or motorised press) with rotation. This enables you to apply a controlled axial force, while applying a rotational movement i.e. tightening.

To optimise the stake's adhesion, you can clean the sphere with clear water, or with an alcohol wipe.

Weight :

Technical specifications:

· Contact sphere:

o Synthetic material

o Adhesive

o Non-scratching

· Adjustable contact surface: approximately Ø 28 to Ø 50

· Attachment: Ø 8 mm; anti-rotation width 8 mm

Adjusting the contact surface:

è Unscrew the small screw using a No. 1.5 Allen key

è Turn the knob using the arrow and the mark for guidance:

· Clockwise to increase the contact surface

· Anti-clockwise to decrease the contact surface

è Screw in the lock screw using the Allen key

APPLICATIONS:

- OPENING CASE-BACKS IN AFTER-SALES / PRODUCTION

- CLOSING CASE-BACKS TO THE FINAL TORQUE

Advantages:

- Works on solid, engraved and sapphire case-backs

- Non-scratching

- Adaptable to most presses on the market

- Interchangeable sphere

Maintenance advice:

Clean the sphere with clear water or an alcohol wipe

Replacing the sphere:

- Unscrew the 6 screws using a No. 1.5 Allen key

- Remove the used sphere and fit the replacement sphere, visually lining up the 6 holes with the 6 screws

- Fully screw in the 6 screws, holding the sphere in position

Handle for universal stake :

For manual use of the stake

This option allows you to use the stake by hand. The knurled handle offers a significant grip to screw or unscrew the bottoms with a strong torque.

The positioning

The handle is positioned on the stake by a pin larger in diameter than the other two to index the handle with respect to the stake.

Removing the handle

To remove the handle from the stake, simply press on the tabs identified by «PRESS» and pull the handle axially.

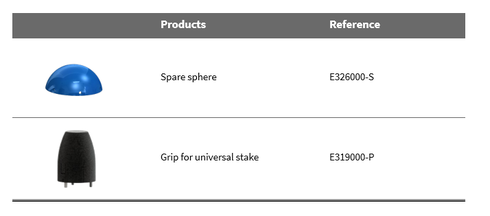

ACCESSOIRES: